| Availability: | |

|---|---|

| Quantity: | |

SLQ

GOLD

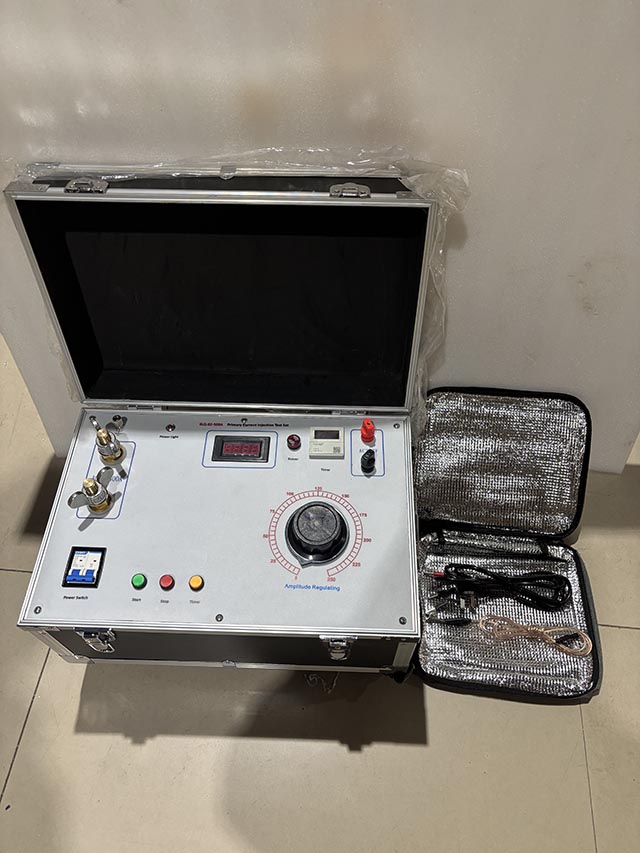

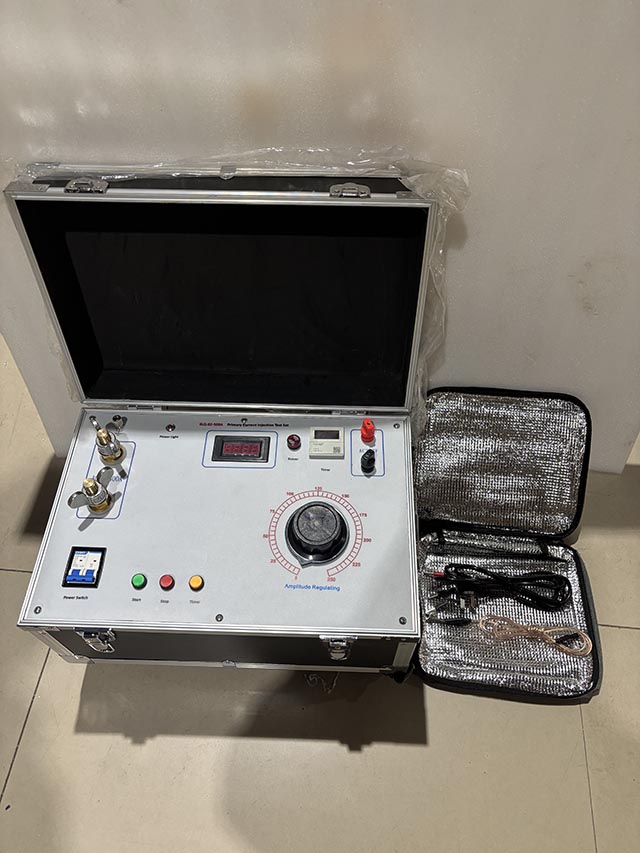

High Current Generator Injector Primary Current Injection Test Set for Circuit Breaker Test

SLQ Primary Current Injection Tester is an advanced and reliable testing instrument designed for the power industry, specializing in performance verification of key power equipment such as circuit breakers, current transformers, and protection relays. By generating stable and controllable high currents, it simulates real-world operating conditions (rated current) and fault scenarios (fault current) of power systems, enabling comprehensive and accurate testing. With its flexible structural design, customizable functions, and excellent technical performance, this tester is widely recognized as an indispensable tool in power system testing and maintenance.

Strong Customization Capability: Supports customization of key parameters such as output current, power supply voltage, and timer specifications (4/5/6-digit) according to user requirements, fully meeting the personalized testing needs of different projects.

Dual Structural Design: Integral models (≤5KVA) are compact and portable, suitable for on-site testing with limited space; separated models (>5KVA) feature independent control units and current boosters, ensuring efficient heat dissipation and stable operation during high-power, long-duration tests.

Comprehensive Testing Functions: Covers three core testing applications—protection system verification, CT calibration, and circuit breaker testing—and can also be used as an AC high-current source for other power equipment tests, realizing multi-purpose use of one machine.

High Safety and Reliability: Strictly adheres to safety operation standards, with mandatory grounding requirements, power-off wiring rules, and high-temperature warning reminders to avoid operational hazards. The equipment adopts high-quality components and precise circuit design, ensuring long-term stable operation and low failure rate.

Easy Operation and Maintenance: The control unit integrates key components such as variable transformers and ammeters, with a simple and intuitive operation interface. The standard configuration includes complete technical documents (user manual, pass certificate, factory report) to facilitate equipment use and maintenance.

| Parameter | Range/Specification |

|---|---|

| Power Supply | AC220V / AC400V (45Hz~65Hz) |

| Maximum Output Current | 500A ~ 25000A |

| Current Distortion | <5% |

| Impedance Voltage | >8% |

| Idle Current | >6% |

| Current Measurement Accuracy | Class 0.5 |

| Operating Environment | Temperature: 0~40℃; Humidity: <90% |

| Structural Type | Integral (≤5KVA) / Separated (>5KVA) |

| Optional Timer | Multiple time ranges, accuracy 0.1%RDG+1D (max) |

| Standard Configuration | Control unit, current booster (separated models), user manual, pass certificate, factory report |

Laboratory Calibration: Used in electrical laboratories for accurate calibration of current transformers, ensuring the measurement accuracy of CTs before they leave the factory.

On-Site Maintenance: Applied in on-site maintenance of power plants and substations to test the performance of circuit breakers and protection relays, quickly identifying potential faults and ensuring the reliable operation of power equipment.

Product Type Testing: Utilized by electrical equipment manufacturers for type testing of circuit breakers, verifying their thermal stability and operational reliability under rated current conditions.

Power System Debugging: Employed in power system debugging projects to test the responsiveness of protection systems, ensuring the coordinated operation of various components and improving the overall safety and stability of the power grid.

High Current Generator Injector Primary Current Injection Test Set for Circuit Breaker Test

SLQ Primary Current Injection Tester is an advanced and reliable testing instrument designed for the power industry, specializing in performance verification of key power equipment such as circuit breakers, current transformers, and protection relays. By generating stable and controllable high currents, it simulates real-world operating conditions (rated current) and fault scenarios (fault current) of power systems, enabling comprehensive and accurate testing. With its flexible structural design, customizable functions, and excellent technical performance, this tester is widely recognized as an indispensable tool in power system testing and maintenance.

Strong Customization Capability: Supports customization of key parameters such as output current, power supply voltage, and timer specifications (4/5/6-digit) according to user requirements, fully meeting the personalized testing needs of different projects.

Dual Structural Design: Integral models (≤5KVA) are compact and portable, suitable for on-site testing with limited space; separated models (>5KVA) feature independent control units and current boosters, ensuring efficient heat dissipation and stable operation during high-power, long-duration tests.

Comprehensive Testing Functions: Covers three core testing applications—protection system verification, CT calibration, and circuit breaker testing—and can also be used as an AC high-current source for other power equipment tests, realizing multi-purpose use of one machine.

High Safety and Reliability: Strictly adheres to safety operation standards, with mandatory grounding requirements, power-off wiring rules, and high-temperature warning reminders to avoid operational hazards. The equipment adopts high-quality components and precise circuit design, ensuring long-term stable operation and low failure rate.

Easy Operation and Maintenance: The control unit integrates key components such as variable transformers and ammeters, with a simple and intuitive operation interface. The standard configuration includes complete technical documents (user manual, pass certificate, factory report) to facilitate equipment use and maintenance.

| Parameter | Range/Specification |

|---|---|

| Power Supply | AC220V / AC400V (45Hz~65Hz) |

| Maximum Output Current | 500A ~ 25000A |

| Current Distortion | <5% |

| Impedance Voltage | >8% |

| Idle Current | >6% |

| Current Measurement Accuracy | Class 0.5 |

| Operating Environment | Temperature: 0~40℃; Humidity: <90% |

| Structural Type | Integral (≤5KVA) / Separated (>5KVA) |

| Optional Timer | Multiple time ranges, accuracy 0.1%RDG+1D (max) |

| Standard Configuration | Control unit, current booster (separated models), user manual, pass certificate, factory report |

Laboratory Calibration: Used in electrical laboratories for accurate calibration of current transformers, ensuring the measurement accuracy of CTs before they leave the factory.

On-Site Maintenance: Applied in on-site maintenance of power plants and substations to test the performance of circuit breakers and protection relays, quickly identifying potential faults and ensuring the reliable operation of power equipment.

Product Type Testing: Utilized by electrical equipment manufacturers for type testing of circuit breakers, verifying their thermal stability and operational reliability under rated current conditions.

Power System Debugging: Employed in power system debugging projects to test the responsiveness of protection systems, ensuring the coordinated operation of various components and improving the overall safety and stability of the power grid.