| Availability: | |

|---|---|

| Quantity: | |

GDKZ-IV

GOLD

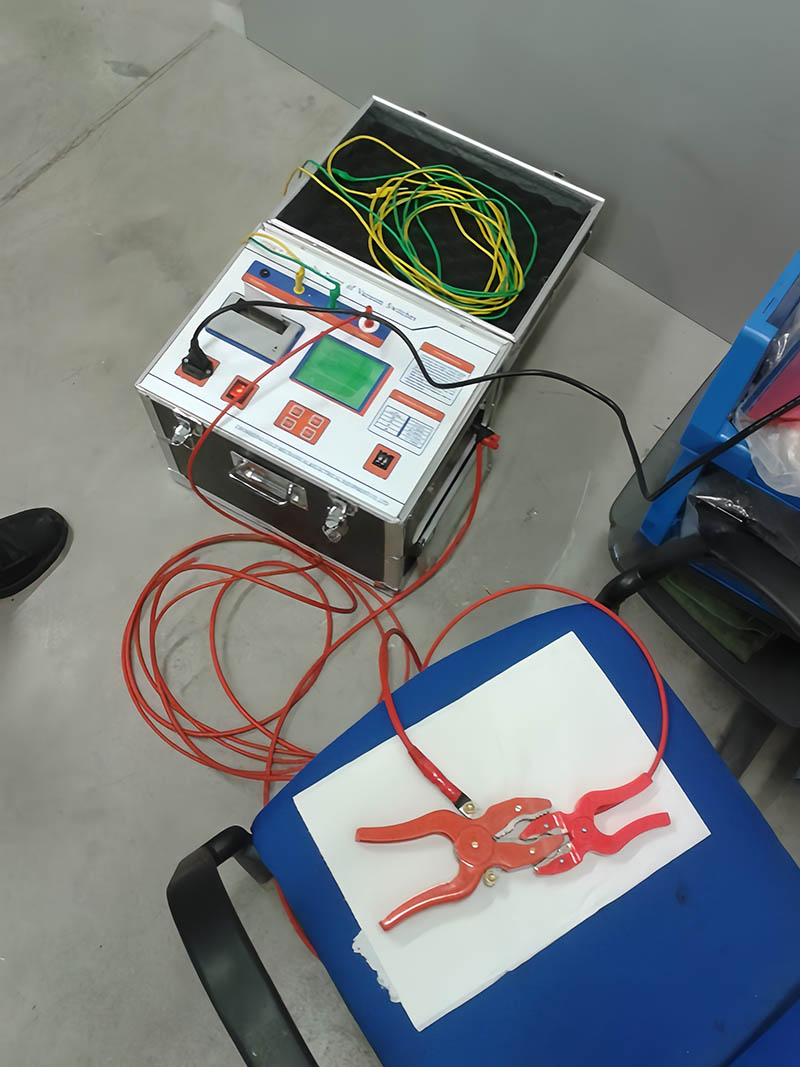

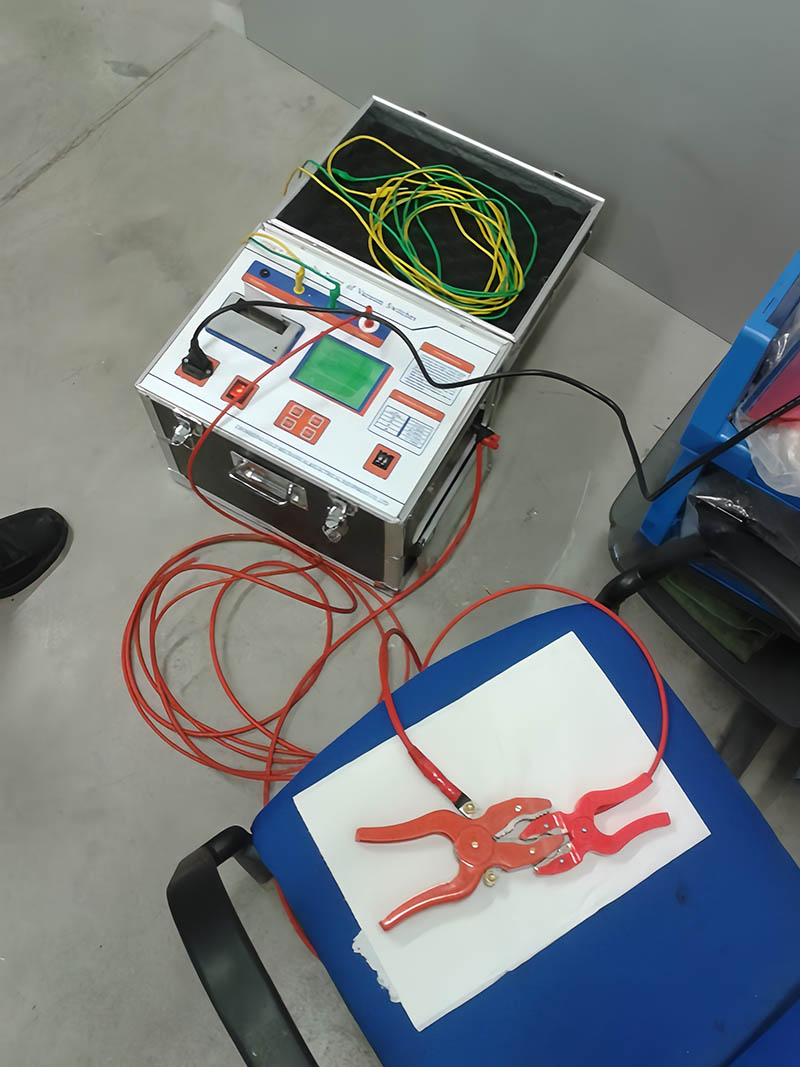

Portable VCB Test Vacuum Degree Tester of Circuit Breaker Vacuum Interrupter Tester with High-speed Printer

Non-Disassembly Design: Innovative excitation coil installation method allows side mounting around the arc chamber, avoiding the need for disassembly and reinstallation. This reduces professional workload and prevents damage to the arc chamber during disassembly.

Early Fault Detection: Unlike traditional frequency withstand voltage methods that only detect severe degradation, this tester can identify vacuum degradation at the early stage (10⁻²~10⁻¹ Pa), enabling timely maintenance and replacement, and reducing maintenance costs.

High Adaptability: Compatible with vacuum tubes of different diameters (classified into four types via DIP switch), suitable for various models of vacuum switches. It operates normally in a temperature range of -20℃~40℃, adapting to harsh on-site environments such as high and low temperatures.

Dual Testing Procedures: Leak detection first excludes severely leaky vacuum tubes, avoiding unnecessary quantitative testing. Quantitative measurement provides accurate vacuum values, ensuring test result reliability.

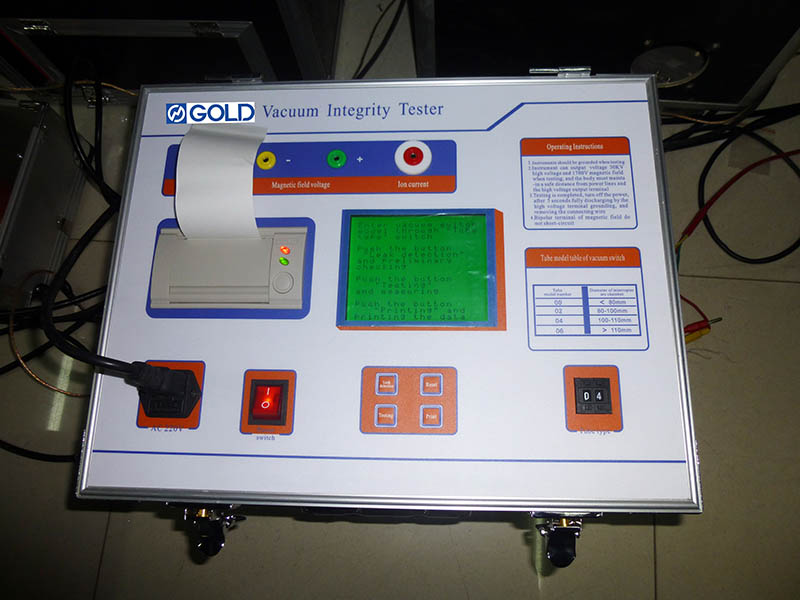

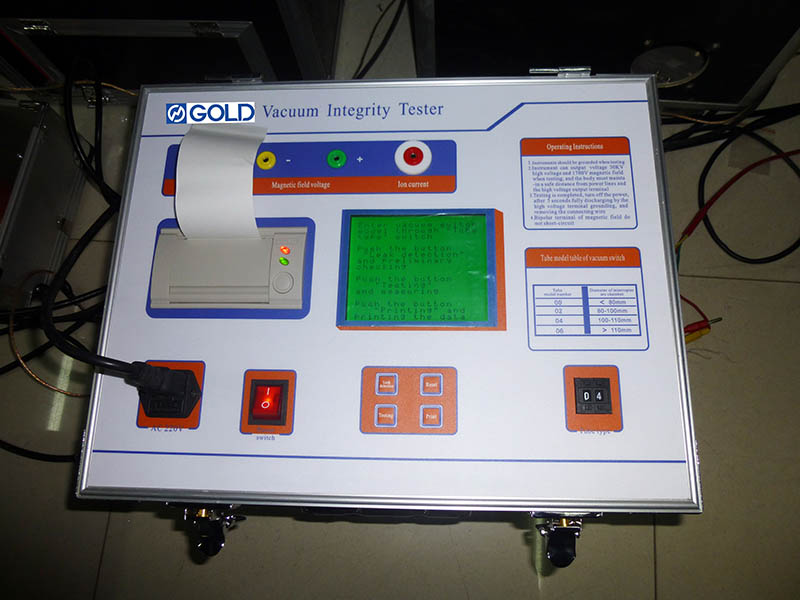

Intelligent Automation: The single-chip microcomputer automatically controls the testing process—charging, voltage application, data analysis, and discharge. Operators only need to follow simple steps, reducing the learning curve.

Safe & Reliable: Equipped with multiple safety protection measures, including protective grounding, automatic discharge after testing, and high-voltage isolation. Clear wiring instructions prevent misconnection, ensuring operator and equipment safety.

Practical Data Management: Built-in printer supports on-site report printing for immediate documentation. Test results are displayed in scientific notation, which is intuitive and easy to record. It can also calculate the allowable storage time of the arc chamber based on test data.

| Category | Details |

|---|---|

| Core Function | Non-destructive measurement of internal vacuum of vacuum interrupter arc chambers |

| Compliance Standard | JB8738-1998《Vacuum Interrupter Arc Chamber of 3.6-40.5KV AC High Voltage Switchgear》 |

| Measurement Range | 10⁻⁵~10⁻¹ Pa |

| Measurement Accuracy | ±10% (for all sub-ranges) |

| Key Voltages | Magnetic field voltage: 1700V; Pulsed electric field high voltage: 30KV |

| Vacuum Tube Classification | Type 00 (<80mm), Type 02 (80~100mm), Type 04 (100~110mm), Type 06 (>110mm) |

| Operating Temperature | -20℃~40℃ |

| Physical Parameters | Weight: 12kg; Dimensions: 420×320×280mm |

| Control System | Single-chip microcomputer (synchronous control, data acquisition, processing) |

| Testing Modes | Leak detection (preliminary assessment), Quantitative measurement (accurate value) |

| Output Interface | Built-in printer |

| Safety Features | Protective grounding, automatic discharge, high-voltage isolation |

Maintenance Optimization: Early detection of vacuum degradation enables predictive maintenance, reducing unplanned downtime.

Quality Control: Ensures vacuum interrupter arc chambers meet standards during production and delivery, improving product reliability.

Cost Reduction: Non-destructive testing reduces disassembly/reinstallation costs and avoids unnecessary replacement of intact arc chambers.

Safety Assurance: Prevents equipment failures caused by vacuum degradation, safeguarding personnel and property safety.

Portable VCB Test Vacuum Degree Tester of Circuit Breaker Vacuum Interrupter Tester with High-speed Printer

Non-Disassembly Design: Innovative excitation coil installation method allows side mounting around the arc chamber, avoiding the need for disassembly and reinstallation. This reduces professional workload and prevents damage to the arc chamber during disassembly.

Early Fault Detection: Unlike traditional frequency withstand voltage methods that only detect severe degradation, this tester can identify vacuum degradation at the early stage (10⁻²~10⁻¹ Pa), enabling timely maintenance and replacement, and reducing maintenance costs.

High Adaptability: Compatible with vacuum tubes of different diameters (classified into four types via DIP switch), suitable for various models of vacuum switches. It operates normally in a temperature range of -20℃~40℃, adapting to harsh on-site environments such as high and low temperatures.

Dual Testing Procedures: Leak detection first excludes severely leaky vacuum tubes, avoiding unnecessary quantitative testing. Quantitative measurement provides accurate vacuum values, ensuring test result reliability.

Intelligent Automation: The single-chip microcomputer automatically controls the testing process—charging, voltage application, data analysis, and discharge. Operators only need to follow simple steps, reducing the learning curve.

Safe & Reliable: Equipped with multiple safety protection measures, including protective grounding, automatic discharge after testing, and high-voltage isolation. Clear wiring instructions prevent misconnection, ensuring operator and equipment safety.

Practical Data Management: Built-in printer supports on-site report printing for immediate documentation. Test results are displayed in scientific notation, which is intuitive and easy to record. It can also calculate the allowable storage time of the arc chamber based on test data.

| Category | Details |

|---|---|

| Core Function | Non-destructive measurement of internal vacuum of vacuum interrupter arc chambers |

| Compliance Standard | JB8738-1998《Vacuum Interrupter Arc Chamber of 3.6-40.5KV AC High Voltage Switchgear》 |

| Measurement Range | 10⁻⁵~10⁻¹ Pa |

| Measurement Accuracy | ±10% (for all sub-ranges) |

| Key Voltages | Magnetic field voltage: 1700V; Pulsed electric field high voltage: 30KV |

| Vacuum Tube Classification | Type 00 (<80mm), Type 02 (80~100mm), Type 04 (100~110mm), Type 06 (>110mm) |

| Operating Temperature | -20℃~40℃ |

| Physical Parameters | Weight: 12kg; Dimensions: 420×320×280mm |

| Control System | Single-chip microcomputer (synchronous control, data acquisition, processing) |

| Testing Modes | Leak detection (preliminary assessment), Quantitative measurement (accurate value) |

| Output Interface | Built-in printer |

| Safety Features | Protective grounding, automatic discharge, high-voltage isolation |

Maintenance Optimization: Early detection of vacuum degradation enables predictive maintenance, reducing unplanned downtime.

Quality Control: Ensures vacuum interrupter arc chambers meet standards during production and delivery, improving product reliability.

Cost Reduction: Non-destructive testing reduces disassembly/reinstallation costs and avoids unnecessary replacement of intact arc chambers.

Safety Assurance: Prevents equipment failures caused by vacuum degradation, safeguarding personnel and property safety.